Solar Roof top requirements

As the capacity of installed solar energy capacity is fast increasing day by day, it is of paramount importance to understand the various technical requirements for the components in the solar photo voltaic power systems. The Ministry of New and Renewable Energy (M.N.R.E.), Govt. of India has been prescribing the technical requirements for the various components of the solar PV system from time to time. In addition to the MNRE requirements, the state Governments also prescribe certain standards as when the need arises.

Rooftop Requirements

The rooftop where the solar panels are to be installed should be free of any shadows as shadows will hamper the generation of solar energy. Though 100 Sq. ft. is enough to cover 1 KW of solar panels, an additional 30 sq. ft. will help in proper spacing and to maintain the system. The space between the solar panels and the parapet walls should be at least 2 ft. In countries above equator, the solar panels has to be faced facing south at an inclined angle and in countries below equator, the solar panels has to be placed facing north at an inclined angle. The angle of inclination depends on the latitude of the geographical location. For example, for installation in Tamil Nadu, India, the angle of inclination should be between 11 – 13 degrees. There should be enough gap between subsequent rows of solar panels so that any shadow can be avoided.

System Requirements

As mentioned above, the components must meet certain test standards prescribed by M.N.R.E., (Ministry of New and Renewable Energy), Govt. of India. The details are elaborated below.

Requirements of Solar Photo Voltaic (PV) array

The solar Photo Voltaic (PV) modules must adhere to the latest edition of the related IEC or equivalent BIS certification for PV module design qualifications.

The standards are below

| Sl. No. | Certifications | PV Module Type |

|---|---|---|

| 1 | IEC 61215 / IS14286 | Crystalline Silicon Terrestrial PV Modules |

| 2 | IEC 61646 / Equivalent IS (Under Dev.) | Thin Film Terrestrial PV Modules |

| 3 | IEC 62108 | Concentrator PV Modules & Assemblies |

| 4 | IEC 61730 Part 1- requirements for construction | All PV modules |

| 5 | IEC 61730 Part2 - requirements for testing, for safety qualification or Equivalent IS | All PV modules |

| 6 | IEC 61701 / IS 61701 (Salt Mist Corrosion Testing) | All PV modules to be used in a highly corrosive atmosphere (coastal areas,etc.) |

Radio Frequency Tag

The Radio Frequency Tag has to be inside the module laminate. The following information has to be in the RF ID Tag.

- Name of the manufacturer of PV Module

- Name of the Manufacturer of Solar cells

- Month and year of the manufacture (separately for solar cells and module)

- Country of origin (separately for solar cells and module)

- I-V curve for the module

- Peak Wattage, Im, Vm and FF for the module

- Unique Serial No and Model No of the module

- Date and year of obtaining IEC PV module qualification certificate

- Name of the test lab issuing IEC certificate

- Other relevant information on traceability of solar cells and module as per ISO 9000 series.

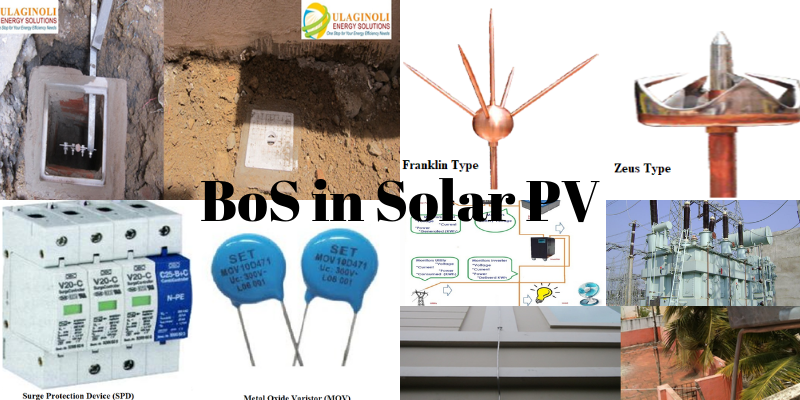

Requirements of Balance of the System

The balance of system should meet the below listed technical requirements.

| Sl. No. | Equipment | Standard Description | Standard Number |

|---|---|---|---|

| 1 | Charge Controller/MPPT units | Environmental Testing | IEC 60068-2 (1,2,14,30) / Equivalent BIS Std. |

| 2 | Power Conditioners/ Inverters**including MPPT and Protections | Efficiency Measurements | IEC 61683 / IS 61683 |

| Environmental Testing | IEC 60068-2 (1, 2, 14, 30) / Equivalent BIS Std. |

||

| 3 | Storage Batteries | General Requirements & Methods of Testing Tubular Lead Acid / VRLA / GEL Capacity Test Charge/Discharge Efficiency Self-Discharge | As per relevant BIS Std. |

| 4 | Cables | General Test and Measuring Method PVC insulated cables for working voltage up to and including 1100 V and UV resistant for outdoor installation | IEC 60227 / IS 694 IEC 60502 / IS 1554 (Pt. I & II) |

| 5 | Switches/Circuit Breakers /Connectors | General Requirements Connectors –safety A.C. /D.C. | IEC 60947 part I,II, III / IS 60947 Part I,II,III EN 50521 |

| 6 | Junction Boxes /Enclosures for Inverters/Charge Controllers/Luminaries | General Requirements | IP 54(for outdoor)/ IP 21(for indoor) as per IEC 529 |

Minimum Warranty Requirements

M.N.R.E. has prescribed warranty requirements for the components which are listed below.

| Sl. No. | Equipmenmt | Minimum Warranty Requirement |

|---|---|---|

| 1 | Solar PV Module | output peak watt capacity should not be less than 90% at the end of 10 years and 80% at the end of 25 years. |

| 2 | Solar Inverter and Charge Conrollers | 5 Years |

| 3 | AC Distriubtion Board and DC Distribution Board | 5 Years |

| 4 | Structures | 5 Years |

| 5 | Storage Batteries | 5 Years |

Authorized Test Centres

The components should be tested at Test Centres authorized by MNRE (Ministry of New and Renewable Energy). Approvals from NABL/ IEC Accredited Testing Laboratories are also accepted.